Automotive Engineering

Next-Gen Automotive Engineering: CFD & FEA-Based Powertrain, NVH, Combustion & Thermal Simulation

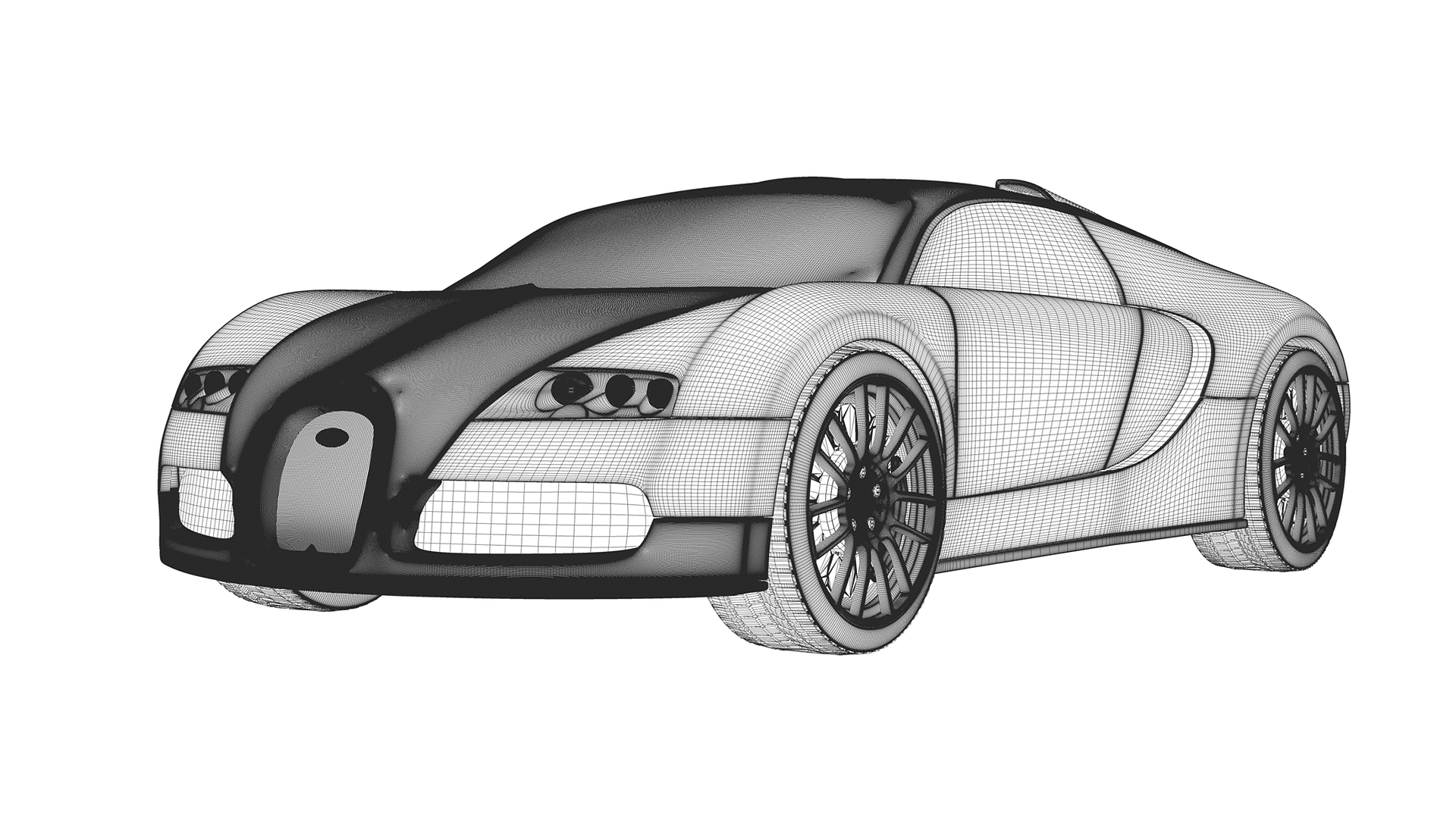

We focus on strategic use of CAE to Optimise Designs, investigate and resolve problems, and minimise time and cost to market. Advanced geartrain modelling and analysis software packages, provides the foundation of concept and definitive design for all driveline and transmission projects that we undertake.

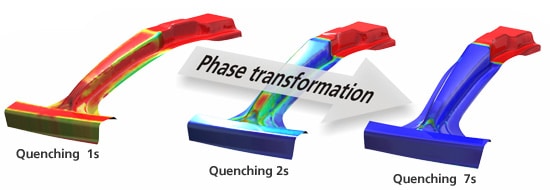

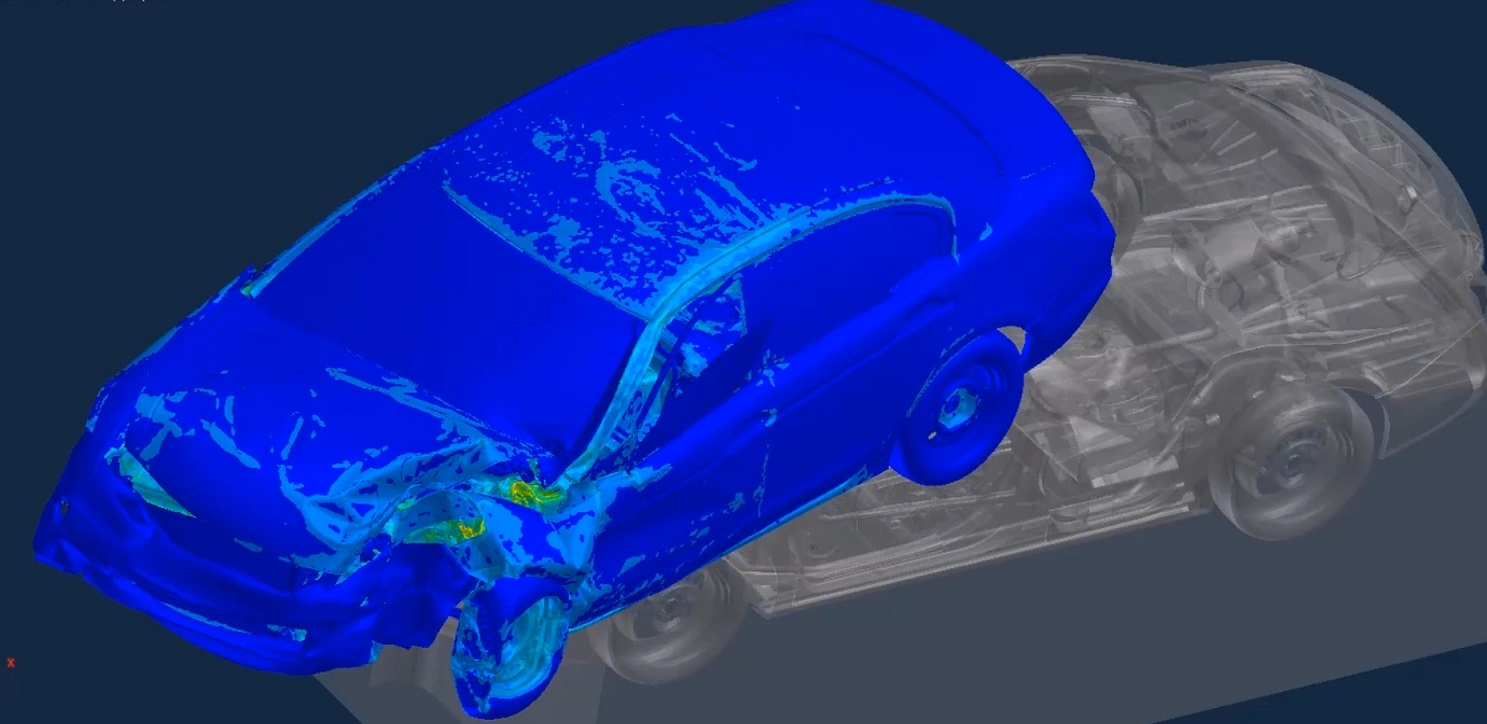

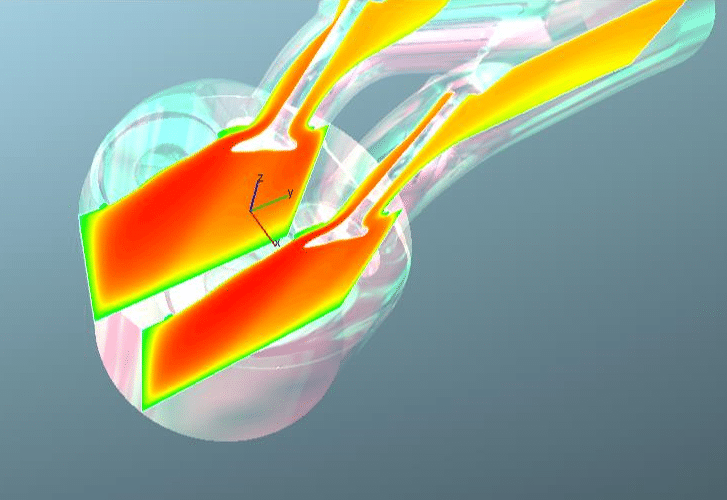

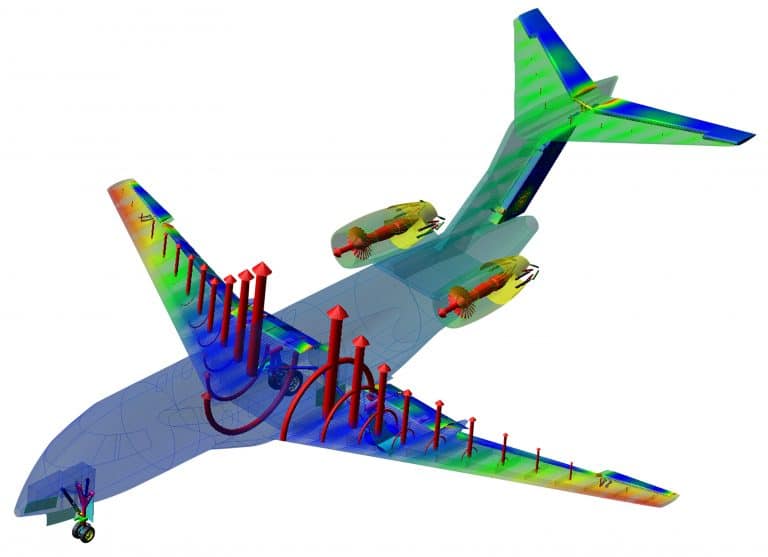

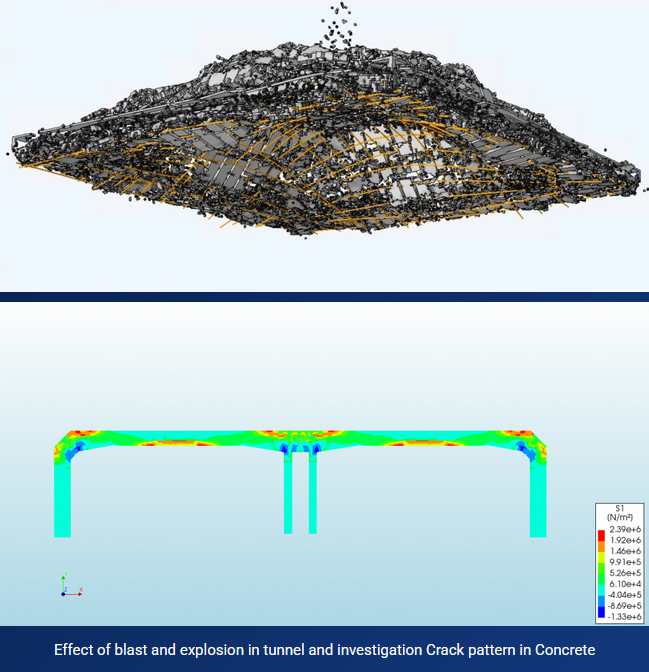

Powertrain component development involves the design and optimization of various components such as engines, transmissions, and axles. FEA and CFD-based simulation can be used to evaluate the structural integrity, fluid dynamics, and thermal performance of these components, allowing engineers to optimize designs and improve performance.

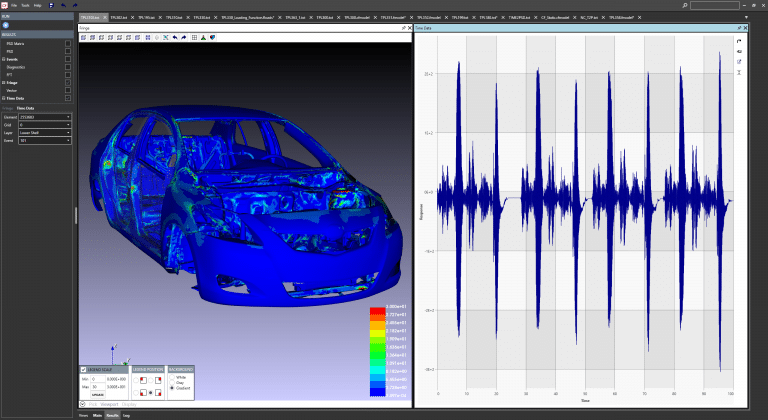

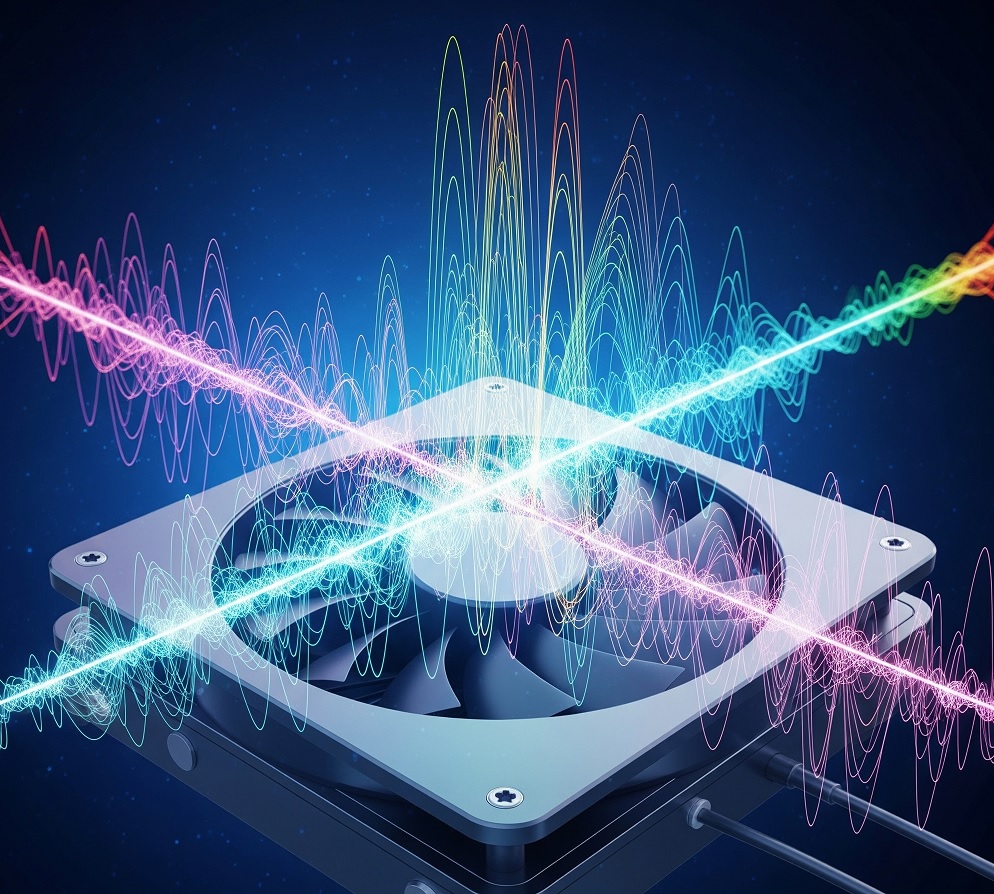

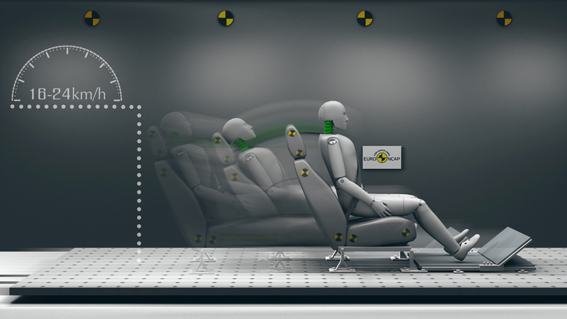

NVH is another important consideration in automotive engineering. By using FEA-based simulation and analysis tools, engineers can evaluate the vibration and noise levels of various components, helping to identify and resolve potential issues before physical prototypes are built.

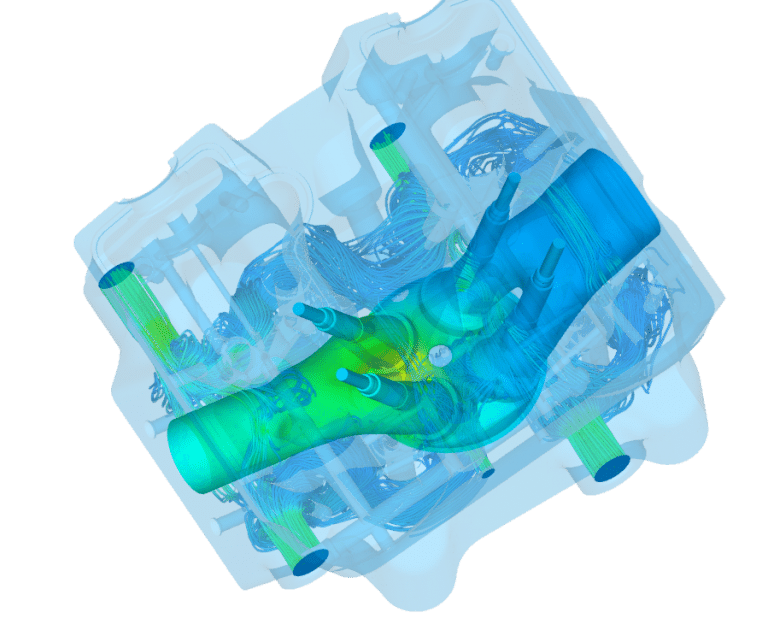

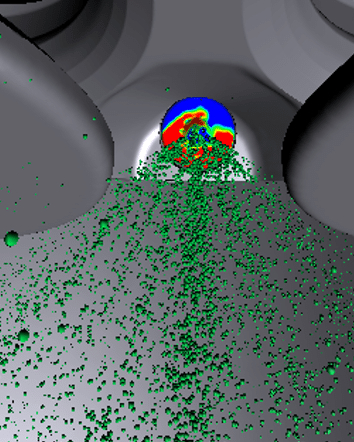

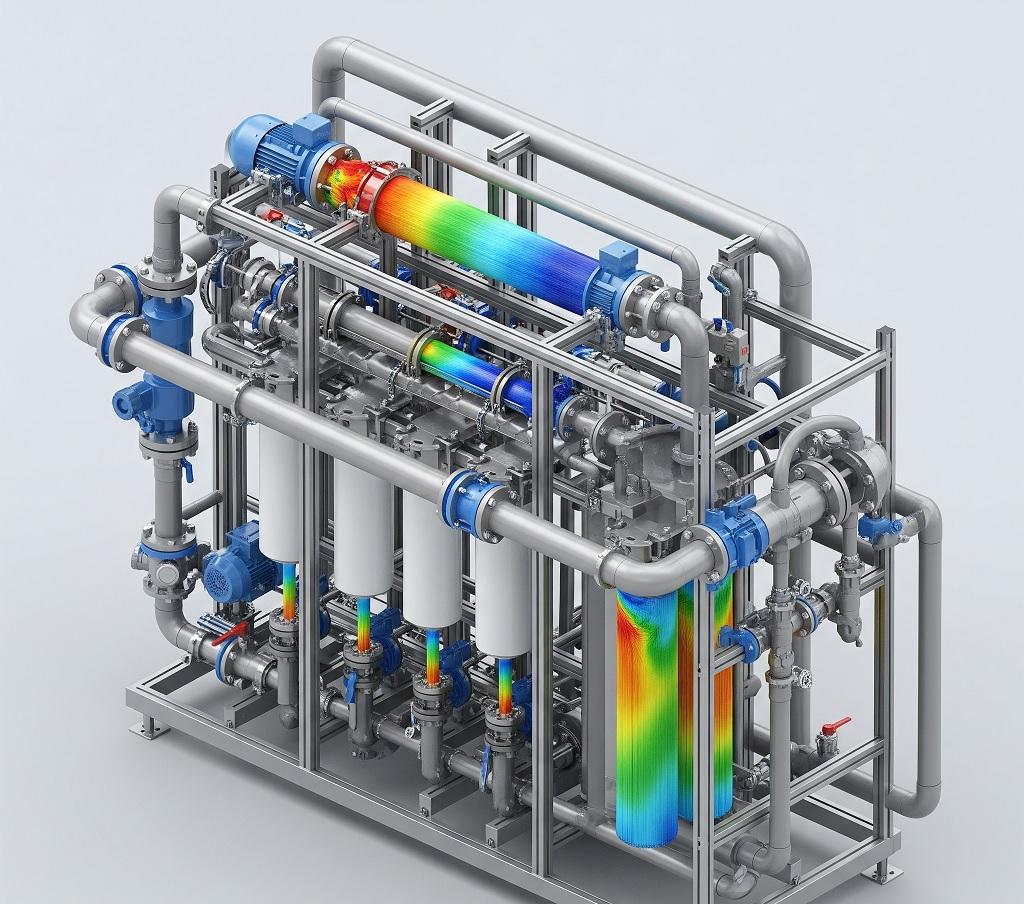

Combustion and thermal simulation are also critical areas in the design of automotive components. By using CFD-based simulation tools, engineers can model and analyze the behavior of combustion processes and thermal systems, allowing them to optimize designs for efficiency and performance.